MECA CUP 1 – 3 Pedal Set with Baseplate

MECA CUP 1 – 3 Pedal Set with Baseplate

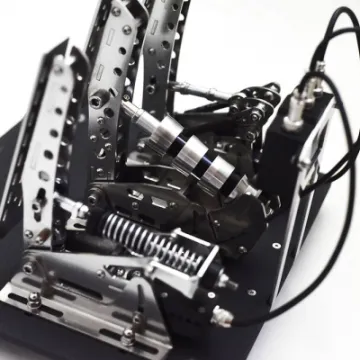

MECA CUP 1 pedal kit is equipped with a brake pedal with built-in "Load Cell" technology for ultra-precision braking in racing games, includes 3 mm thick stainless steel pedals and has adjustable pressure settings for each pedal. Made to last. Ultimate piece of sim racing hardware.

High-quality 3mm-thick stainless steel sim-racing pedals with load-cell technology.

THROTTLE PEDAL

Bronze slide bearings

Loadcell sensor

Board for signal conversion from load cell (analogue-digital)

Solid construction, no unwanted movements or squeaks. Excellent response and feel, and fully adjustable. Made to last using quality materials, electronics, and bronze machined components.

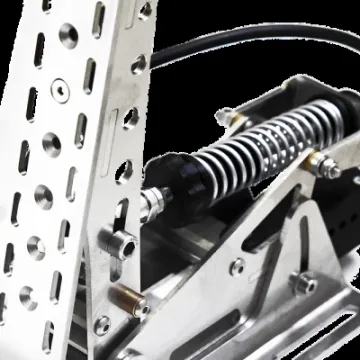

The pedals' shape and length are optimised for the heel-and-toe technique. The pedal can be tilted forward by loosening the rear screws in the round groove in the rear of the pedal. The grooves allow the pedal to tilt by 18°. The pedal height can be adjusted at the front part or by moving the rear remote posts.

The pedal's stiffness can also be adjusted by moving the uni-ball in the pedal lever's groove (main stiffness setting), and fine-tuning the stiffness with the locking wheel pre-tensioning the spring.

The pedal surface is treated with ballotin (glass blasting) to improve adhesion.

BRAKE PEDAL

Loadcell sensor 200Kg

Bronze slide bearings

Aluminium brake segments

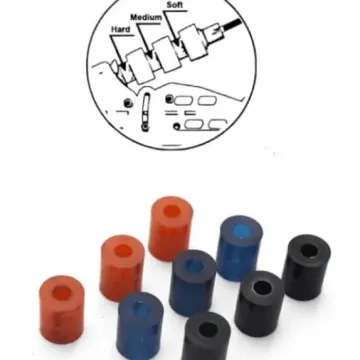

Three different hardness levels using replaceable polyurethane washers

The pedal can be adjusted both in height and longitude

Replaceable polyurethane rollers for pedal hardness adjustment

The brake pedal includes rollers of three levels of hardness: black – soft (pre-fitted to the pedal); blue – medium; orange – hard. Exchanging roller types across different hardness levels affects the braking system's feedback and feel, and combining roller types affects the linearity of pedal stiffness.

CLUTCH PEDAL

Bronze slide bearing

Loadcell sensor

Custom board for signal conversion from load cell (analogue-digital)

Adjustable height and longitudinal position

As per the throttle pedal, this clutch pedal can be tilted forward by loosening the rear screws in the round groove at the rear of the pedal, which allows the pedal to tilt by 18 °. The pedal surface is treated with ballotin (glass blasting) to improve adhesion.

The clutch pedal operates on a cradle principle with pre-tensioned springs. The system works by depressing the pedal along a predefined trajectory; at a given point, the cradle tips over, reducing pressure on the foot. Additionally, the pedal force can be adjusted by repositioning the pedal lever in its groove.

Another important benefit occurs when the polyurethane stoppers engage while the brake pedal is fully depressed. When contact is made, the brake simulates a pressurised brake system with no more pedal movement. This causes a hard brake pedal, producing a feel similar to breaking in a real car.

BASEPLATE

8mm thick steel plate

Powder lacquered

Mounting point for the electronics box

Grooves enable independent adjustment of each pedal's position

Pedals are attached to the rig by 4 screws, M8 and M6

Pedals are equipped with high-quality load cell sensors and supplied with aluminium polyurethane stoppers. Each polyurethane piece is equipped with its own stopper (aluminium bowl). This ensures that each polyurethane roller is protected against its marginal limit load and can be loaded to its weight limit. Once the limit is breached, the rollers become kegs, and the attached sensors are no longer capable of reading the force applied to the pedal as the force is expelled out of the axis. This design minimises excessive deformation, eliminates the unpleasant pedal-drop sensation, and extends the roller's service life. Stoppers prevent excessive deformation, significantly extend the service life of polyurethanes, and improve overall braking performance. Solid construction.

Handmade in the Czech Republic

For further technical information, you can email your enquiry to our specialist team, and we will get back to you as soon as we can.

About Us

Race@home launched in 2020, offering immediate shipment of high-end sim hardware to frustrated customers. Our acclaimed LowRider 5DOF and new LowSlider 6DOF platforms prioritise compact excellence.

Contact Us

raceathome@gmail.com

+441163326679

Leicester, United Kingdom

WhatsApp

Instagram

Facebook

TrustPilot

YouTube